CATHTIP Catheter Tipping, Bonding, Flaring and Hole Drilling

Manufacturing Solutions

1

1

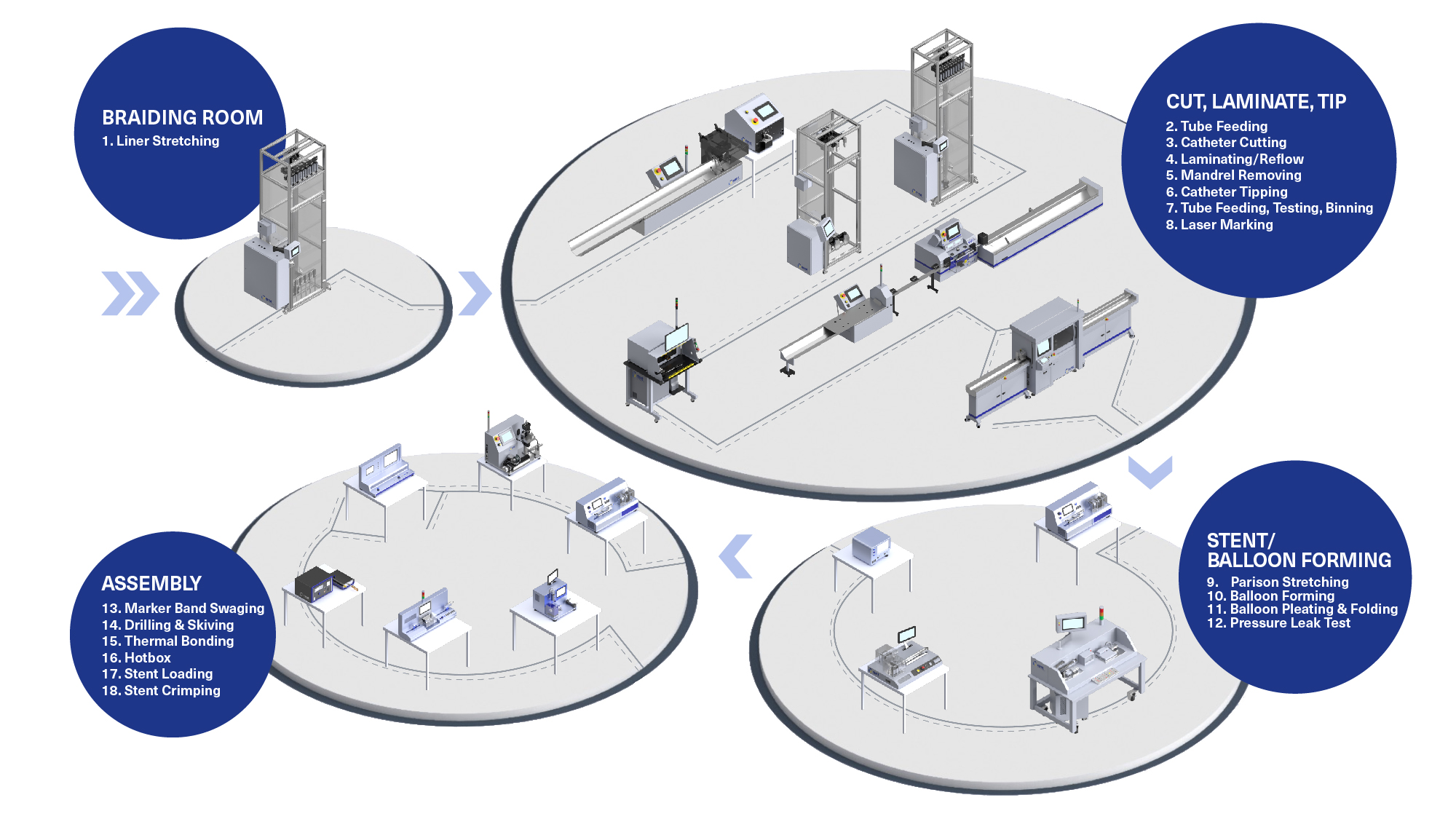

Liner Stretching

Tube Feeding

Catheter Cutting

Laminating/Reflow

Mandrel Removing

Catheter Tipping

Tube Feeding, Testing, Binning

Laser Marking

Parison Stretching

Balloon Forming

Balloon Pleating and Folding

Pressure Leak Test

Marker Band Swaging

Drilling & Skiving

Bonding/Welding

Hotbox

Stent Loading

Stent Crimping

Cathtip Manufacturing Solutions

Recognized globally for producing flash-free, burr-free tips, bonds, and welds, CATHTIP continues to innovate its solutions with patient wellbeing in mind.